Tiltco has adapted its manufacturing processes to eliminate negative environmental impact through skillful and sensitive production. Tiltco realizes as a manufacturer the responsibilities of creating an energy efficient window to conserve energy and efficiency.

Our appreciation for the environment extends beyond creating beautiful views.

Tiltco’s unique glazing systems shape the style of some jaw-dropping, stunning vistas. We inject greenery and a touch of nature into spaces with our floor to ceiling windows and doors, creating seamlessness between the inside and outdoor environments.

We consider the environmental impact in everything we do, from our manufacturing processes, production and creating an energy efficient product. We incorporate non-toxic and eco-friendly materials across our product suite.

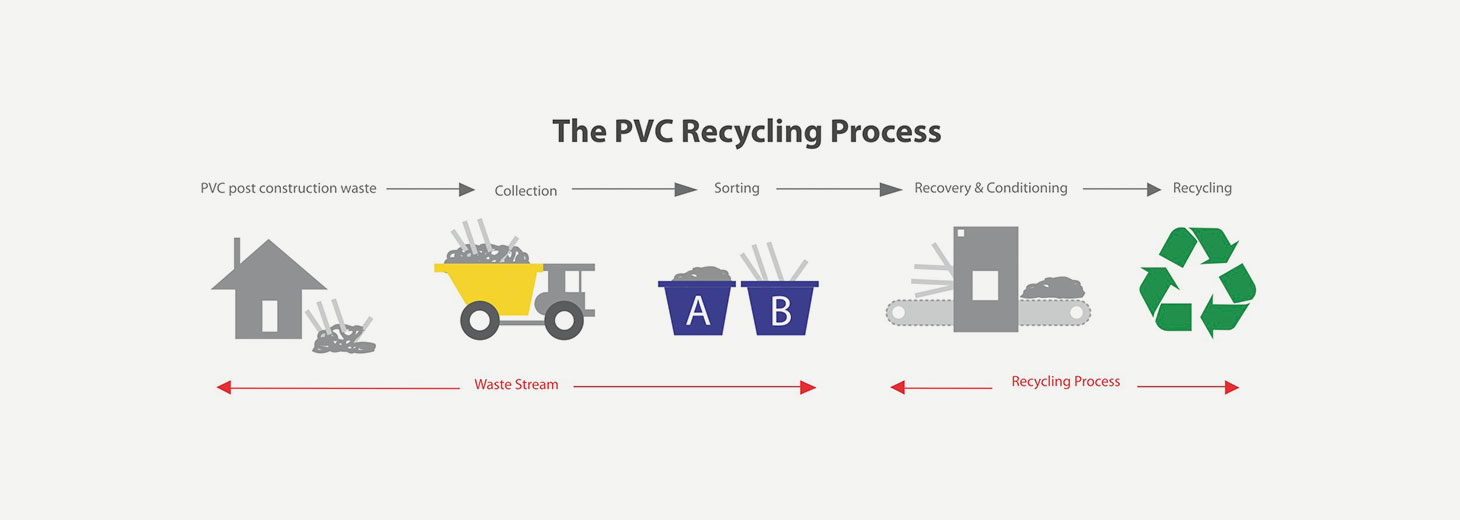

Recycling initiatives.

Tiltco minimizes negative environmental impacts from production methods through a comprehensive recycling program, covering all aspects of manufacturing waste. We work with external recycling agencies to ensure our waste is processed environmentally consciously. Wherever possible, our technical components are produced from recycled materials.

Selecting sustainable materials.

We primarily use aluminum and Unplasticized Polyvinyl Chloride (uPVC) across our range of products. Aluminum and uPVC windows are proven to be one of the most sustainable and environmentally friendly glazing solutions on the market.

The manufacturing of aluminum and uPVC windows requires two-thirds less energy than FiberGlass and steel frame windows and is also lightweight, requiring less energy for transportation.

Aluminum and uPVC windows are energy efficient which reduces the consumption of heating and cooling energy, helping to keep electricity costs down and positively contributing to environmental design accreditations, such as LEED, passive house and net zero housing.

Aluminum & uPVC: our glazing preference

Tiltco utilizes aluminum and uPVC for its far reaching environmental benefits, some of these include:

- Aluminum and uPVC/vinyl requires little or no maintenance creating a healthier, cleaner environment by only requiring a mild detergent and water for cleaning.

- Aluminum and uPVC/vinyl is deployed mainly from natural resources primarily refined oil products and salt.

- Aluminum and uPVC/vinyl has the lowest production energy and raw material requirements and emissions of any window and door manufacturing process.

- Aluminum and uPVC/vinyl is a very safe material to construct fenestration products from in that it self extinguishes when in contact with flame.

- Aluminum and uPVC/vinyl is strictly monitored by manufacturing standards to continually eliminate the negative effects of vinyl production on the environment.

HIGH DURABILITY, LOW MAINTENANCE

Aluminum and vinyl windows are impervious to rot, rust, corrosion, blistering, flaking, and infestation by termites or other insects. Aluminum and vinyl resists attacks by fungus and mildew, and scratching a vinyl window will not require any touch-ups.